Insulation and energy consumption

What Determines the efficiency of a professional refrigerated cell?

A practical guide to selecting high-performance systems and reducing operating costs

Energy efficiency is now one of the primary criteria when choosing a professional refrigerated cell. But what truly affects energy consumption? And how can you determine whether a system is engineered to ensure thermal stability and cost control?

This article clarifies the most important technical parameters.

1. Insulation: the core of efficiency

The factor that most significantly influences energy consumption is the thickness and density of the insulation.

High-density panels reduce thermal dispersion, improving:

- temperature uniformity

- reduced compressor cycling

- stability even with frequent door openings

- lower mechanical stress on components

This is the first feature to evaluate when comparing different refrigerated cells.

2. How much can you save with high-quality insulation?

Industry studies show that systems with high-performance insulation can improve energy efficiency by up to 35–40% compared to low-cost solutions using low-density panels.

The benefits are twofold:

- lower annual operating costs

- extended component lifespan

3. How to identify a truly efficient system

Here are three practical indicators:

- high-density panels and joints designed to prevent thermal bridges

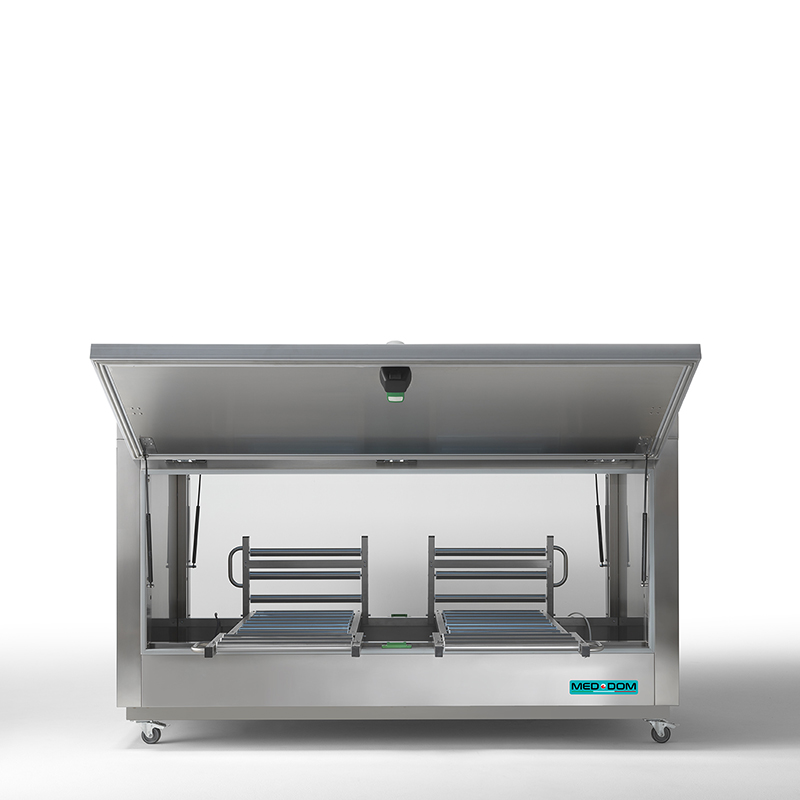

- materials such as stainless steel that enhance hygiene and durability

- digital controls that reduce temperature fluctuations

Together, these elements ensure consistent performance and a more favorable TCO (Total Cost of Ownership).

Does lower energy consumption mean lower power?

No.

Efficiency is not about reducing power, but about delivering power only when needed. A well-insulated cell works less because it loses less cold, not because it generates less refrigeration.

High-quality insulation is the most effective investment for reducing consumption while improving performance.

MedDom technology integrates advanced solutions to ensure long-term reliability and energy savings.